New Build Crack Assessment Tool

Identify Your Crack

This tool helps you determine whether your crack requires professional attention or is likely cosmetic.

Assessment Result

When you move into a brand‑new house, the last thing you expect is a set of hairline lines spider‑webbing across walls or floors. Yet many owners discover that new builds cracks appear surprisingly early. Understanding why this happens, how to stop it, and what to do when it does, saves you time, money, and a lot of stress.

Why do cracks show up in brand‑new homes?

New Build is a residential construction project that is completed and occupied for the first time. Even though a new build is brand‑new, the materials are still adjusting to the environment and loads they never experienced before. The structure settles, the concrete cures, and the soil beneath it may shift. These movements create tension and, eventually, visible cracks.

In most cases the cracks are not a sign of catastrophic failure but a natural part of the building's 'dry‑in' process. However, certain patterns can indicate deeper issues that need professional attention.

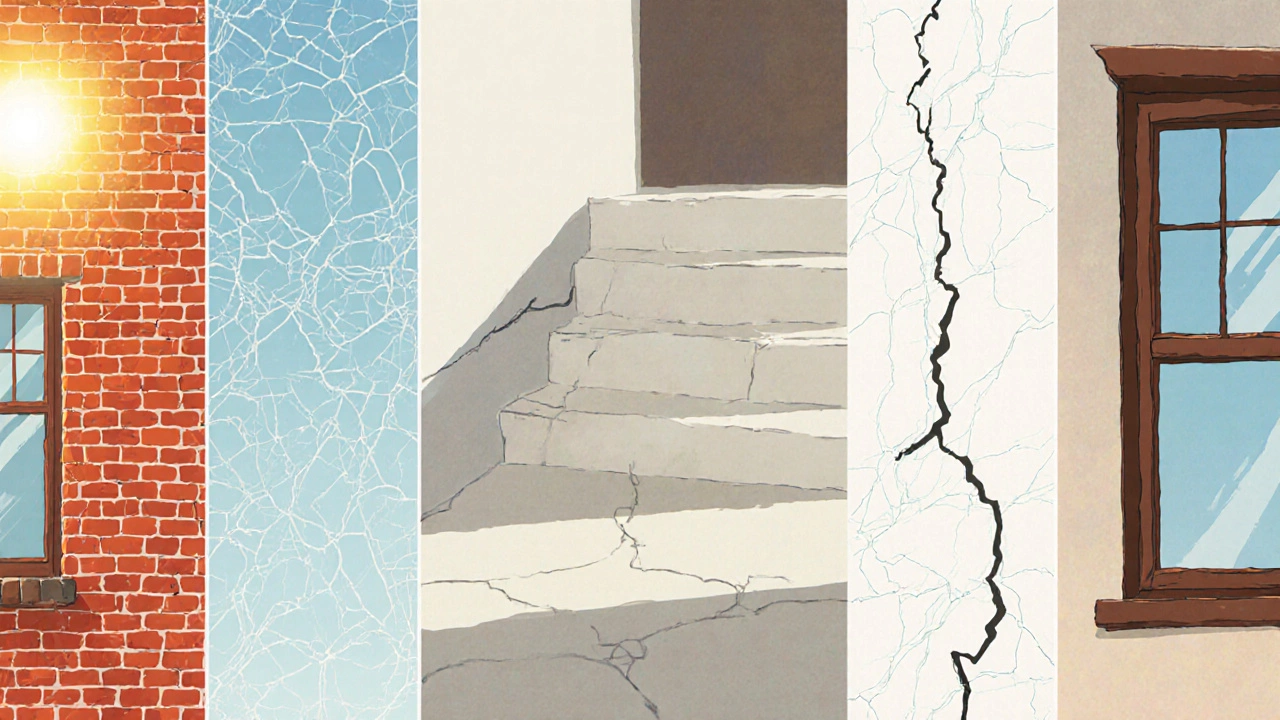

Common Types of Cracks

Identifying the type of crack helps you decide whether it’s harmless or a red flag. Below is a quick reference that matches crack appearance with typical causes.

| Crack Appearance | Location | Common Cause |

|---|---|---|

| Hairline, vertical lines | Exterior brickwork | Thermal expansion of masonry |

| Diagonal, stair‑step pattern | Floor‑to‑wall junction | Settling of Foundation or differential settlement |

| Horizontal cracks | Plaster or drywall | Moisture movement in Concrete slab |

| Map‑crack (network of fine lines) | Large interior walls | Drying shrinkage of plaster or concrete |

| Wide, jagged cracks | Near doors or windows | Improper Construction Joint detailing |

Key Factors That Lead to Cracking

- Foundation movement - when the soil under a footing compresses or expands, the support shifts.

- Soil Settlement - especially on expansive clays or sandy soils that consolidate after the building load is applied.

- Thermal Expansion of brick, concrete, or metal - daily temperature swings cause materials to grow and shrink.

- Construction Joint weaknesses - joints that aren’t properly aligned or sealed become stress concentrators.

- Moisture intrusion - water absorbed by concrete or plaster expands, creating pressure.

- Poor material quality - low‑grade concrete, insufficient reinforcement, or fast‑drying plaster can crack early.

Each factor interacts with the others. For example, a slab on expansive soil that also sees high summer‑day temperature swings is a perfect storm for horizontal concrete cracks.

How to Prevent Cracks During Construction

- Conduct a thorough geotechnical survey. Knowing the soil type lets engineers design appropriate footings, moisture barriers, or piers.

- Use a properly mixed, high‑quality Concrete mix with the right water‑to‑cement ratio and adequate slump for the climate.

- Install control joints in slabs and large walls. Spacing them at 15‑20 times the slab thickness reduces random cracking.

- Apply expansion joints around external walls, windows, and doors to accommodate thermal movement.

- Provide curing time and moisture retention for concrete and plaster. Wet burlap or curing compounds keep moisture from evaporating too quickly.

- Use proper reinforcement - rebar or mesh - to distribute loads and limit crack width.

Building codes in New Zealand, such as NZS 3101 for concrete structures, already embed many of these safeguards, but diligent contractors often go beyond the minimum.

What to Do When You Spot Cracks

Not every crack needs a structural engineer, but you should follow a simple triage:

- Assess size and direction. Hairline cracks (≤0.3mm) that are vertical are usually cosmetic.

- Monitor over time. Mark the ends of a crack with a pencil and re‑measure after a month. If it widens, call a professional.

- Check for moisture. If a crack is accompanied by damp patches or mold, water ingress is likely.

- Seek expert opinion. For diagonal or horizontal cracks in load‑bearing walls, contact a structural engineer quickly.

Most minor cracks can be filled with a flexible epoxy or acrylic filler, then painted over. For larger, structural cracks, underpinning or slab jacking may be required.

Homeowner’s Crack‑Prevention Checklist

- Review the builder’s warranty - many new‑home warranties cover structural cracks for up to 10years.

- Keep the property’s humidity consistent. Use de‑humidifiers in damp seasons.

- Avoid heavy landscaping or large trees close to the house, as root growth can shift the soil.

- Schedule regular inspections during the first two years - early detection is cheaper to fix.

- Maintain proper drainage away from foundations; clean gutters and downspouts regularly.

Frequently Asked Questions

Do all new‑build homes develop cracks?

Most new homes will show some form of minor cracking as the structure settles and materials cure. These are usually superficial and not a sign of structural failure.

How long does it take for a new build to finish settling?

Settlement is most active in the first 12‑24 months, but minor movement can continue for up to 5 years, especially in areas with expansive soils.

What size of crack requires a structural engineer?

Cracks wider than 3mm, horizontal cracks in load‑bearing walls, or any crack that continues to grow should be assessed by a qualified engineer.

Can I repair cracks myself?

Minor hairline cracks can be filled with a flexible filler and repainted. Larger or structural cracks need professional repair to ensure safety.

Does New Zealand’s building code address crack prevention?

Yes. NZS 3101 (Concrete Structures) and NZBC clauses on moisture control set minimum standards for joint spacing, reinforcement, and curing, all of which reduce cracking risk.

Write a comment