Type D Construction Cost Estimator

Estimate Your Project Costs

Get a quick estimate based on 2025 NZ market data for Type D construction projects

Estimated Project Cost

Type D construction is a classification used in NewZealand’s commercial building sector to describe structures built primarily with structural steel as the main load‑carrying framework, supported by concrete floors and fire‑rated cladding. It balances flexibility, speed, and fire performance, making it a popular choice for mid‑rise offices, retail centres, and industrial warehouses.

Quick Takeaways

- Type D construction relies on a steel frame with concrete slabs and fire‑resistant cladding.

- It meets the New Zealand Building Code (NZBC) requirements for structural integrity, fire safety, and energy efficiency.

- Typical projects: 5‑to‑12‑storey office blocks, shopping malls, and light‑industrial units.

- Key benefits: rapid erection, design flexibility, good fire rating, and ease of integrating services.

- Considerations: higher steel costs, need for corrosion protection, and coordination of fire‑rating details.

What Exactly Is Type D Construction?

In the NZ classification system, building types A‑D refer to the primary structural system and fire‑resistance level. Type D denotes a non‑combustible structure where the load‑bearing framework is steel, the floors are typically concrete, and the external envelope uses fire‑rated panels or masonry. Unlike Type A (timber) or Type B (concrete block), Type D does not rely on combustible materials for its main structural role.

The design philosophy is to create a sturdy “skeleton” that can support large spans, accommodate heavy equipment, and provide clear open floor plans. Because steel is non‑combustible, the building achieves a higher fire rating with less reliance on fire‑proofing treatments, though additional fire‑resistant cladding is still required for compliance.

Key Code References and Standards

Any Type D project must satisfy several NZ regulations and Australian‑NewZealand (AS/NZS) standards:

- NZ Building Code covers the overall performance requirements for structure, fire, and energy efficiency - clauses B1 (structural), E2 (fire), and H1 (thermal performance).

- AS/NZS 1170 provides design actions for wind, earthquake, and live loads that the steel frame must resist.

- AS/NZS 4600 details the design of steel structures, including member sizing and connection design.

- NZS 3604 while primarily for timber, its fire‑protection guidelines are referenced when mixed structural systems are used.

Compliance is usually demonstrated through a combination of structural calculations, fire‑engineering reports, and energy‑modelling outcomes. Engaging a chartered professional engineer early helps align the design with these standards.

Typical Applications of Type D Construction

Because of its strength‑to‑weight ratio, Type D works well for projects that need long spans or quick construction cycles:

- Mid‑rise office buildings (5‑12storeys) where column‑free floor plates are valuable for flexible tenancy.

- Retail complexes that require large open‑plan spaces for displays and customer flow.

- Light‑industrial warehouses where overhead crane loads are common.

- Educational facilities that combine classrooms, labs, and auditoriums under one roof.

In Auckland, the boom in mixed‑use developments has pushed many developers to opt for Type D because it can be paired with precast concrete panels-a combination that speeds up the build while meeting strict fire‑rating requirements.

Design Considerations and Best Practices

When planning a Type D project, keep these practical points in mind:

- Corrosion protection. NewZealand’s coastal climate can accelerate steel rust. Galvanised or epoxy‑coated studs, along with proper drainage detailing, are essential.

- Fire rating coordination. Although steel is non‑combustible, connections and small steel components can fail under high temperatures. Use fire‑protected columns or encase critical joints in concrete.

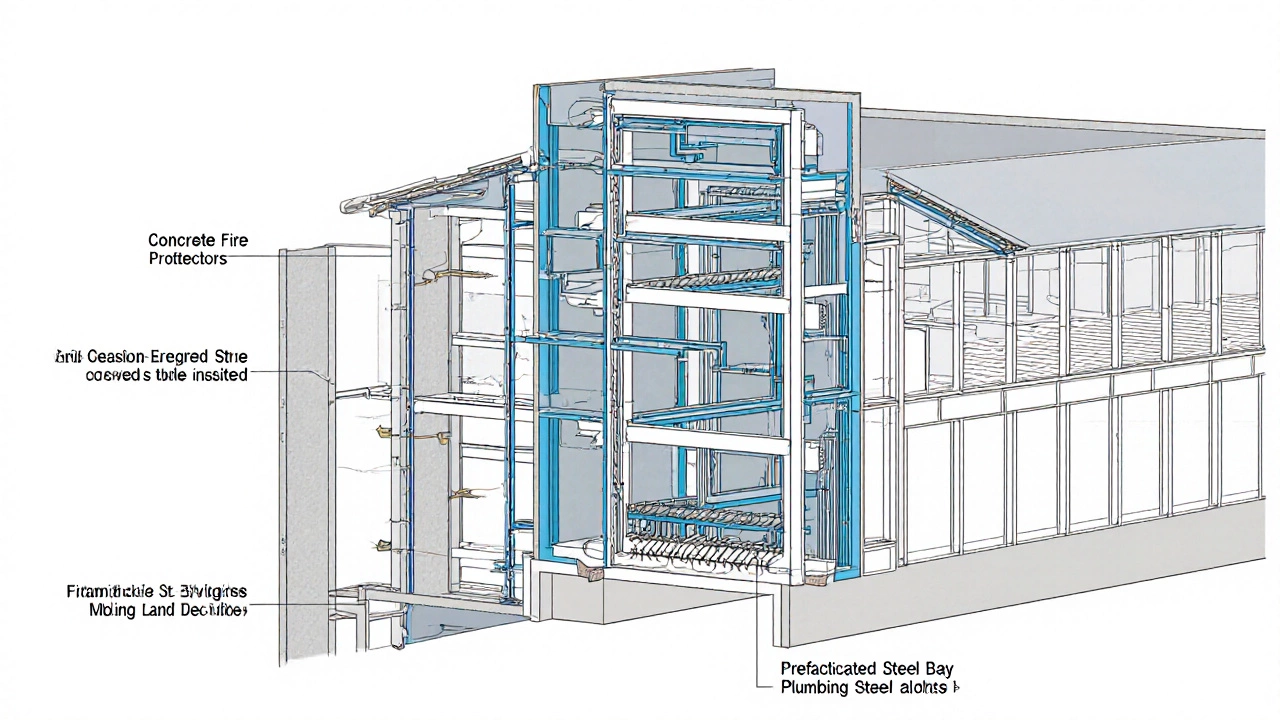

- Service integration. Run mechanical, electrical, and plumbing (MEP) services through the steel frame using concealed sleeves. This maintains the clean aesthetic and reduces post‑construction re‑work.

- Prefabrication opportunities. Off‑site fabrication of steel bays and concrete floor panels can cut on‑site labor by up to 30% and improve quality control.

- Insulation and thermal envelope. Pair fire‑rated cladding with high‑performance insulation (e.g., PIR or mineral wool). This satisfies the NZBC’s H1 clause while keeping operating costs low.

Following these steps not only keeps the project within budget but also reduces the risk of costly change orders during construction.

Cost Implications

Material costs for Type D are generally higher than for timber‑based Type A, mainly because steel prices have been volatile in recent years. However, the faster build schedule often offsets the material premium. A 2025 market survey by the NewZealand Construction Industry Council showed:

- Average steel price: NZ$2,400 per tonne (up 8% YoY).

- Typical cost for a 6‑storey office building: NZ$2,800-2,950 per square metre.

- Time savings: 10‑12weeks less on‑site construction compared with traditional cast‑in‑place concrete.

When you factor in reduced labour, lower finance charges, and earlier occupancy, the overall life‑cycle cost can be comparable-or even lower-than alternative building types.

Sustainability and Environmental Impact

Type D construction can be quite sustainable if you make the right choices:

- Recycled steel. Up to 95% of structural steel can be sourced from recycled scrap, cutting embodied carbon dramatically.

- Energy‑efficient envelope. Combining fire‑rated cladding with high‑R‑value insulation reduces heating and cooling demand, helping meet NZBC Goal6 for carbon emissions.

- Design for de‑construction. Steel frames are easy to dismantle and reuse, supporting circular‑economy principles.

Many developers now pursue Green Star or NABERS ratings for Type D projects, focusing on the steel’s recyclability and the building’s operational performance.

Comparison with Other Building Types

| Aspect | Type A (Timber) | Type B (Concrete Block) | Type C (Concrete Frame) | Type D (Steel Frame) |

|---|---|---|---|---|

| Primary Structure | Timber studs | Concrete masonry units | Reinforced concrete columns/beams | Structural steel columns/beams |

| Fire Rating | Requires extensive fire‑proofing | Inherent fire resistance | Good fire resistance, needs coating | Non‑combustible, minimal coating needed |

| Construction Speed | Moderate | Slow (on‑site block laying) | Fast with precast | Fastest with prefabricated bays |

| Typical Height | Up to 3storeys | Up to 5storeys | 5‑12storeys | 5‑12storeys (can go higher) |

| Cost per m² (2025 NZ$) | 1,800‑2,000 | 2,200‑2,500 | 2,600‑2,800 | 2,800‑2,950 |

| Sustainability | Renewable but low durability | High embodied carbon | Medium carbon, can use recycled aggregate | High recycled content, recyclable |

The table shows why many developers pick Type D for larger, fast‑track projects where fire performance and flexibility are crucial. If your budget is tight and you’re building a low‑rise residential block, Type A or B might make more sense.

Common Pitfalls and How to Avoid Them

Even experienced crews run into issues if they overlook a few details:

- Under‑estimating corrosion. Skipping a corrosion‑risk assessment in coastal zones can lead to premature steel fatigue. Use a marine‑grade coating and design for adequate ventilation.

- Fire‑proofing gaps. Missing fire‑stopping at floor‑to‑wall interfaces compromises the overall rating. Conduct a third‑party fire‑engineer review before handing over to contractors.

- Service clash. Running large ducts through the steel frame without coordination creates rework. Adopt a 3‑D BIM model early to clash‑detect MEP routing.

- Insulation compression. Installing insulation directly against steel without a thermal break can cause heat loss and condensation. Use insulated panels with a vapor barrier.

Addressing these risks during the design phase saves both time and money.

Step‑by‑Step Guide to Planning a Type D Project

- Define program requirements (area, height, load specifications).

- Engage a chartered structural engineer familiar with AS/NZS 1170 to perform seismic and wind load analyses.

- Develop a conceptual steel frame layout using BIM software.

- Coordinate fire‑engineering with the frame design to meet NZBC E2 fire‑rating targets.

- Select fire‑rated cladding and insulation that satisfy both fire and H1 energy clauses.

- Issue a detailed specification for prefabricated steel bays and concrete slabs.

- Run a clash‑detection workshop with MEP contractors.

- Obtain building consent and schedule inspections at key milestones (foundation, frame‑up, fire‑rating tests).

- Monitor construction progress with weekly site reports, focusing on corrosion protection and fireproofing application.

- Complete post‑occupancy evaluation to verify energy performance and fire safety.

Following this checklist keeps the project on track and ensures full compliance with NZ regulations.

Future Outlook for Type D Construction

As Auckland’s skyline evolves, demand for taller, mixed‑use towers will keep growing. Advances in high‑strength steel alloys and modular construction are expected to push Type D heights beyond 20storeys while staying cost‑effective. Moreover, the upcoming revisions to the NZBC (expected 2026) will tighten fire‑performance metrics, driving further innovation in fire‑protected steel connections.

For owners and developers, staying updated on steel technology and code changes will be essential to leverage Type D’s speed and sustainability advantages.

Frequently Asked Questions

What makes Type D construction different from Type C?

Type C uses a reinforced concrete frame, whereas Type D relies on a structural steel skeleton. Steel allows longer spans and faster erection, while concrete offers inherent fire resistance but slower build times.

Is Type D suitable for high‑rise buildings?

Yes, provided the design follows the NZBC’s height‑related structural and fire‑safety clauses. Modern high‑strength steel grades enable heights well above 20storeys when combined with appropriate fire‑proofing.

How does fire rating work for a steel‑frame building?

Steel itself doesn’t burn, but it loses strength at high temperatures. Fire rating is achieved by encasing critical members in concrete, applying intumescent coatings, or using fire‑rated cladding that protects the steel for a prescribed period (usually 60‑120minutes).

What are the main cost drivers for Type D projects?

Key drivers include steel prices, prefabrication logistics, fire‑proofing treatments, and the level of insulation required to meet energy codes. Faster build times can offset higher material costs.

Can I use recycled steel in a Type D building?

Absolutely. Up to 95% of structural steel can be sourced from recycled scrap, which lowers embodied carbon and often meets certification requirements for green building ratings.

Write a comment